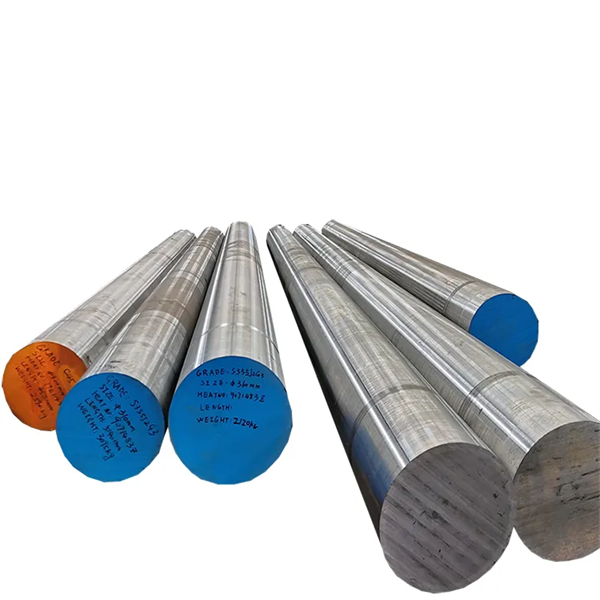

AISI 4140 SCM440 DIN 42CrMo4 1.7225 Forged Alloy Steel Round Bar

Huahana Huahana

Ua wehewehe ʻia ʻo AISI 4140 ma ke ʻano he kila kila haʻahaʻa nona ka 1% Cr-Mo e like me ka hoʻoikaika ʻana i nā mea hoʻohuihui. ʻilihune i ka weld hiki i nā hiʻohiʻona.AISI 4140 ka mea maʻamau i hoʻolako ʻia i ke kūlana quenched a me ka paʻakikī 28-32HRC.

He ikaika kiʻekiʻe ka 4140, hiki ke paʻakikī, paʻakikī, a me ka deformation i ka wā e kinai ana.Loaʻa iā ia ka ikaika kolo kiʻekiʻe a me ka ikaika hoʻomanawanui i nā wela kiʻekiʻe.Hoʻohana ʻia no ka hana ʻana i nā forgings e koi ai i ka ikaika kiʻekiʻe a me nā ʻāpana hoʻopau a me nā ʻāpana ʻoi aku ka nui ma mua o ke kila 4135, e like me nā mīkini nui no ka locomotive traction, booster transmission gears, hope axles, connecting rods a me nā kiʻi puna i hoʻouka nui ʻia.

Hōʻike

| inoa mea kūʻai | AISI 4140 SCM440 DIN 42CrMo4 1.7225 Forged Alloy Steel Round Bar | |

| Mea waiwai | ASTM | 4140 |

| DIN | 42crmo4 | |

| GB | 42CrMo | |

| Kūlana | GB/T799, ASTM A29, A108, A321, A575, BS970, DIN1652, JIS G4051 | |

| OD | 6mm a 600mm | |

| Ili | Ua pena ʻeleʻele, ʻaʻahu ʻole, i ʻoni ʻia, i uhi ʻia ma Chrome | |

| Nā kikoʻī | pā pōʻai | 8mm~800mm |

| pā kihi kihi | 3mm * 20mm * 20mm ~ 12mm * 800mm * 800mm | |

| Paʻa huinaha | 4mm * 4mm ~ 100mm * 100mm | |

| pā pālahalaha | 2*10mm~100*500mm | |

| Hexagonal | 4mm~800mm | |

| Kūlana | Hana ʻia;ʻOwili wela;Huki anu | |

| Kaʻina hana | Hoʻoheheʻe ʻia ka umu uila, hoʻopaʻa ʻia a hoʻopili ʻia, huli ʻia ka pahu pōʻai. | |

| ʻoʻoleʻa: | HBS 217Max (ʻokoʻa mai ka mālama wela) QT 28-32HRC | |

| Hoao UT | SEP 1921/84/2 C/c papa. | |

| Hoʻomanawanui | Dia -0/+ 0~5mm, Mānoanoa -0/+ 0~5mm, Laulā: -0/+ 0~10mm. | |

| Ka lōʻihi | 2m,4m,5.8m,6m,11.8m,12m a i ole e like me ka makemake. | |

| Pūʻolo | Hoʻopili pono kai. | |

AISI 4140 pae like

| ʻāina | Kina | Iapana | Kelemānia | USA | Pelekania |

| Kūlana | GB/T 3077 | JIS G4105 | DIN (W-Nr.) EN 10250 | AISI/ASTM ASTM A29 | BS 970 |

| Papa | 42CrMo | SCM440 | 42crmo4/1.7225 | 4140 | EN19/709M40 |

AISI 4140 mea kila kemika(%)

| Papa | C | Si | Mn | P | S | Cr | Mo |

| 42CrMo | 0.38-0.45 | 0.17-0.37 | 0.5-0.80 | ≤0.035 | ≤0.035 | 0.9-1.2 | 0.15-0.25 |

| SCM440 | 0.38-0.43 | 0.15-0.35 | 0.6-0.85 | ≤0.035 | ≤0.04 | 0.9-1.2 | 0.15-0.30 |

| 42crmo4/1.7225 | 0.38-0.45 | ≤ 0.4 | 0.6-0.9 | ≤0.025 | ≤0.035 | 0.9-1.2 | 0.15-0.30 |

| 4140 | 0.38-0.43 | 0.15-0.35 | 0.75-1.00 | ≤0.035 | ≤0.04 | 0.8-1.1 | 0.15-0.25 |

| EN19/709M40 | 0.35-0.45 | 0.15-0.35 | 0.5-0.80 | ≤0.035 | ≤0.035 | 0.9-1.5 | 0.2-0.40 |

AISI 4140 mea kila kila

| Papa | Kuʻi ikaika σb(MPa) | Hāʻawi ikaika σs (MPa) | ʻO ka lōʻihi δ5 (%) | Hoemi ψ (%) | Ka hopena Waiwai Akv (J) | ʻoʻoleʻa |

| 4140 | ≥1080 | ≥930 | ≥12 | ≥45 | ≥63 | 28-32HRC |

Palapala noi

Loaʻa ka AISI 4140 kila i nā noi he nui e like me ka forgings no ka aerospace, aila a me ke kinoea, automotive, mahiʻai a me nā ʻoihana pale etc. , nā ʻāpana logging, shafts, sprockets, studs, pinions, pump shafts, ram, and ring gears etc.

ʻO ka hōʻoia maikaʻi

1. Koʻikoʻi e like me nā koi

2. Laʻana: Loaʻa ka laʻana.

3. Nā ho'āʻo: ho'āʻo paʻakai paʻakai/Tensile ho'āʻo / Eddy manawa / Chemical haku ho'āʻo e like me nā mea kūʻai mai noi

4.Certificate: IATF16949, ISO9001, SGS etc.

5. EN 10204 3.1 Hōʻoia