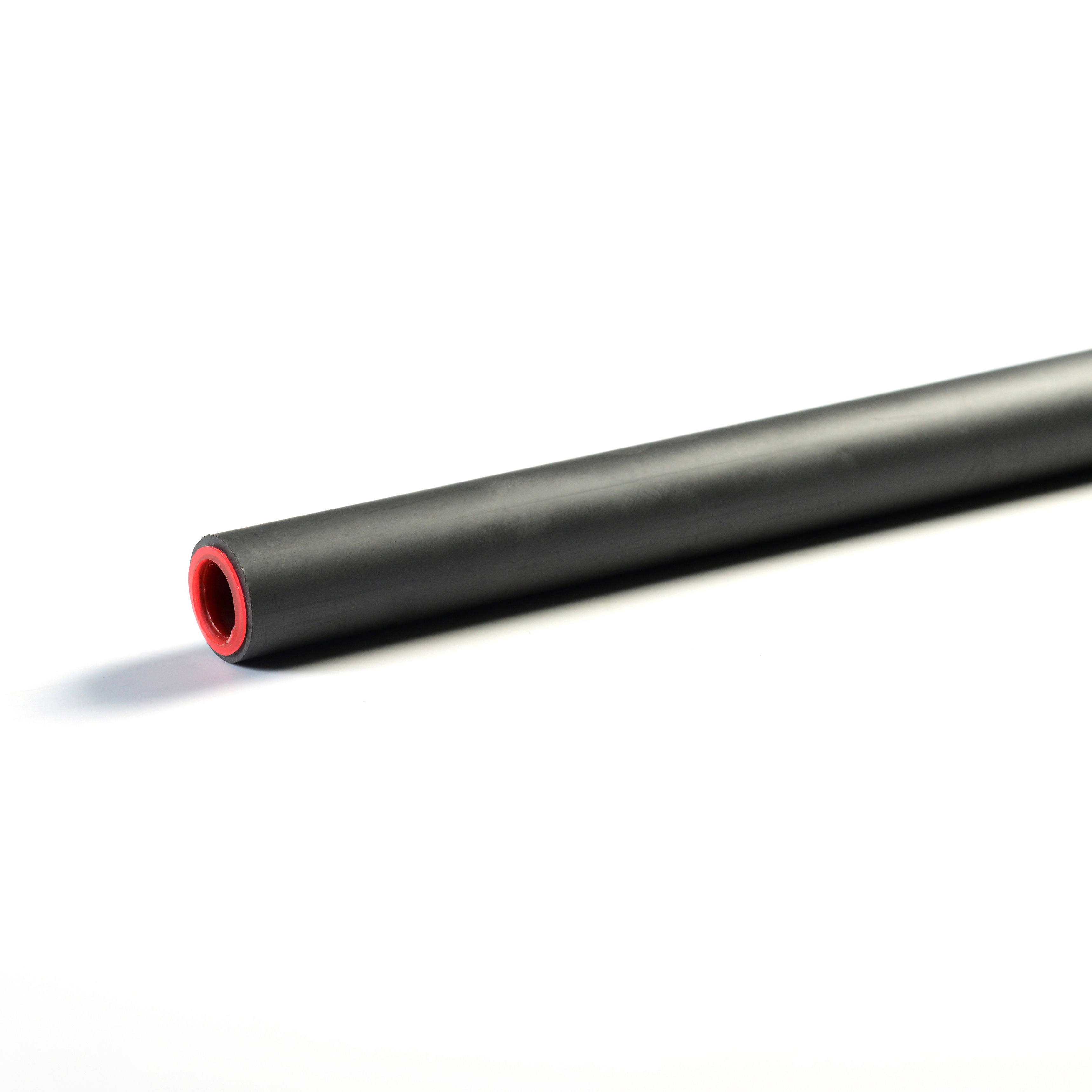

phosphat pololeiedpaipuHe ʻano hou ia o ka paipu kūpaʻa ʻaʻahu, e hoʻohana ana i ka ʻenehana hoʻohui pūnana wili.Hoʻokumu ʻia ia e ka hana mechanical o ka milo ʻana i ka nesting composite o ʻelua mau mea metala maka, me ka hoʻohana ʻana i ka ʻepekema i ka mānoanoa o ka pā paipu kumu waho e hoʻokō ai i ke kaomi hana o ka ʻōnaehana pipeline, a me ka hoʻohana ʻana i ka paipu hoʻoheheʻe ʻana i ka corrosion-resistant alloy pipe e amo i ka. nā koi corrosion o ka ʻōnaehana pipeline.

Ke hoʻohālikelike ʻia me ka hao kuʻuna ʻaʻahu kūʻokoʻa, ke kila hoʻoheheʻe ʻia, ke kila seramika i hui pū ʻia, a me ka paipu pōhaku, kēia phosphat pololei.ed ʻO nā mea maikaʻi o ka paipu.

1. ʻAʻahu maikaʻi ke kūpaʻa.

2. Ke kū'ē kū'ē kiʻekiʻe, kūpono i nā pae kiʻekiʻe.

3. Hoʻopili paʻa ʻia ka ʻili o loko me ka paipu kila o waho, a koho ʻia kahi kaʻina hana kūikawā e hana i kahi hui fusion ma waena o nā papa hana, e hōʻoia ana i ka hilinaʻi o ka hana.

4. He kū'ē maikaʻi i ka haʻalulu mechanical a me ka haʻalulu wela.

5. Hoʻohui pono pono.Hiki ke hoʻohana ʻia nā flanges a me nā hono hiki ke hoʻohana ʻia no ka hoʻopili ʻana, a hiki ke ʻoki a welded ma ka makemake.

Ka laulā o ka hoʻohana:

Pūnaehana hoʻoheheʻe ʻana i ka pauka lanahu, ka paipu lawe lehu maloʻo maloʻo, a me ka ʻōnaehana lanahu pōhaku i nā mea kanu wela

Nā ʻōnaehana lawe pneumatic ʻē aʻe no nā ʻāpana pauka

ʻO ka ʻōnaehana hoʻokele hydraulic slag a me ka lawe ʻana i ka slurry me ka nui o ka nui

Ka lawe ʻana i nā ʻano mea eli

1. Ka hopena Phosphating

(1) Ka hopena o ka phosphating ma mua o ka uhi ʻana

① E hoʻonui i ka hoʻopili ʻana ma waena o ka papa uhi (e like me ka pena pena) a me ka mea hana.

② E hoʻomaikaʻi i ka pale ʻana i ka corrosion o ka uhi ʻana o ka mea hana ma hope o ka uhi ʻana.

③ E hoʻomaikaʻi i ka hoʻonani.

(2) Ka hopena o ka phosphating non coating

① E hoʻomaikaʻi i ka pale ʻana o ka mea hana.

② E hōʻoia i ka maʻalahi o ka mea hana i ka wā e hana ai.

③ Hoʻomaikaʻi i ka pale ʻana i ka corrosion o ka mea hana.

2. Hoʻohana i ka phosphating

Hoʻohana nui ʻia ka phosphating kila no ka pale ʻana i ka corrosion a ma ke ʻano he kiʻiʻoniʻoni kumu no ka pena.

(1) Phosphating film no ka pale ʻana i ka corrosion

① Hoʻohana ʻia ke kiʻi phosphating pale no ka mālama ʻana i ka corrosion o nā ʻāpana kila.ʻO ke ʻano o ka phosphating film hiki ke zinc a manganese.ʻO ka nui o kēlā me kēia'āpana o ka membrane he 10-40 g / m2.E kau i ka aila anti rust, ka momona, ka wax, a pela aku ma hope o ka phosphating.

② Kiʻiʻoniʻoni Phosphating no ka substrate pena

E hoʻonui i ka pili a me ka pale ma waena o ke kiʻi pena a me nā mea hana kila.ʻO ke ʻano o ke kiʻi phosphating hiki ke hoʻokumu i ka zinc a i ʻole ka zinc calcium.He 0.2-1.0 g/m2 ka nui o ka hui o ke kiʻi phosphating (hoʻohana ʻia no ka papa lalo o ka pena ma nā ʻāpana kila deformation nui);1-5 g/m2 (hoʻohana ʻia no ka papa lalo o ka pena ma nā ʻāpana kila maʻamau);5-10 g/m2 (no ka papa kumu pena o nā ʻāpana kila ʻaʻole i hoʻololi ʻia).

(2) Ka uhi ʻana o ka Phosphate no ka maʻalahi o ka hana anuanu

ʻO ke kaumaha o ke kiʻiʻoniʻoni no kēlā me kēia wahi o ka uea kila a me ke kaha kiʻi paipu kila welded he 1-10 g / m2;ʻO ke kaumaha o ke kiʻiʻoniʻoni no kēlā me kēia ʻāpana o ke kaha kiʻi kiʻi kiʻi phosphating tube he 4-10 g/m2;ʻOi aku ka nui o ke kaumaha o ke kiʻiʻoniʻoni no kēlā me kēia ʻāpana o ka extrusion anuanu o nā ʻāpana kila ma mua o 10 g/m2.

(3) Ka uhi ʻana o ka Phosphate no ka hōʻemi ʻana i ka friction

Hiki i ke kiʻi Phosphating ke hōʻemi i ka friction.ʻO ka maʻamau, hoʻohana ʻia ka phosphating e pili ana i ka manganese, a hiki ke hoʻohana pū ʻia ka phosphating based zinc.No nā mea hana me nā āpau kūpono liʻiliʻi, ʻo ka nui o ke kiʻi phosphating he 1-3 g / m2;No nā mea hana me nā āpau kūpono kūpono (gearbox gears), ʻo ka nui o ke kiʻi phosphating he 5-20 g/m2.

(4) Hoʻopili Phosphate no ka hoʻokuʻu uila

ʻO ka maʻamau, hoʻohana ʻia ka zinc based phosphating.Hoʻohana ʻia no ka mālama ʻana i ka wafer phosphating silicon i nā kaʻa a me nā transformers.

Ka manawa hoʻouna: ʻAukake-24-2023