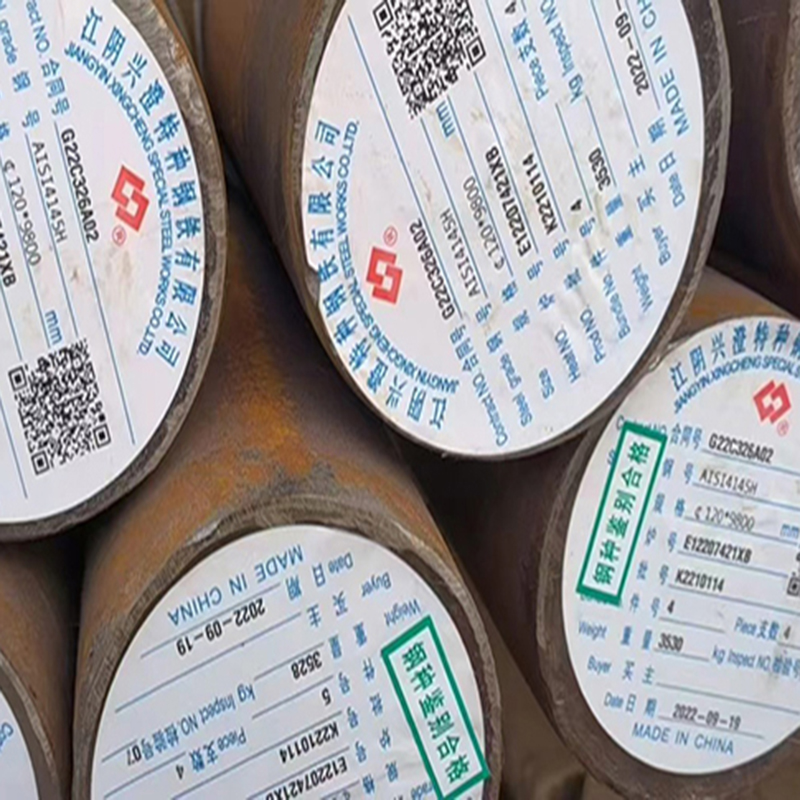

SAE4130 Steel Round Bar AISI 4130 Alloy Steel Bar

Ke ʻimi nei mākou i ka ʻōlelo hoʻokele o ka "Quality is exceptional, Assistance is supreme, Reputation is first", a e hana maoli a kaʻana like i ka kūleʻa me nā mea kūʻai aku a pau no SAE4130 Steel Round Bar AISI 4130 Alloy Steel Bar, Ke ʻimi mau nei mākou e hoʻokumu i ka pilina me nā mea hoʻolako hou e hoʻolako i ka holomua a me ka naʻauao i kā mākou mea kūʻai waiwai.

Ke ʻimi nei mākou i ka manaʻo hoʻokele o ka "Quality is exceptional, Assistance is supreme, Reputation is first", a e hana maoli a kaʻana like i ka kūleʻa me nā mea kūʻai aku āpau no4130 Bara hao, Manaʻolana mākou hiki iā mākou ke hoʻokumu i ka hui lōʻihi me nā mea kūʻai a pau.A lana ka manaʻo e hiki iā mākou ke hoʻomaikaʻi i ka hoʻokūkū a hoʻokō i ke kūlana win-win me nā mea kūʻai aku.Hoʻokipa maikaʻi mākou i nā mea kūʻai mai ka honua holoʻokoʻa e hoʻokaʻaʻike mai iā mākou no kekahi mea āu e makemake ai!

Nā hiʻohiʻona

ʻO 4130 4135 4140 4145H nā pahu kila he kila haʻahaʻa kalapona.Aia lākou i ka Chrome-Molly alloy i loaʻa i ka chromium a me ka molybdenum i mea hoʻoikaika ikaika.

ʻO 4130 ka pahu kila a puni ka hana maikaʻi, ka liʻiliʻi o ka hoʻololi ʻana, a me ke kūpaʻa luhi maikaʻi.Aia ia i ka ʻāpana o ke kila hiki ke paʻakikī i waena.Ma hope o ka hoʻomaʻamaʻa ʻana i ka wela, 4140 ka ikaika maikaʻi a me nā waiwai mechanical piha, hiki ke hana maikaʻi, a me nā hua kiʻekiʻe.ʻO ka mahana lawelawe he 427 degere Celsius.

He ikaika kiʻekiʻe ka 4140, hiki ke paʻakikī, paʻakikī, a me ka deformation i ka wā e kinai ana.Loaʻa iā ia ka ikaika kolo kiʻekiʻe a me ka ikaika hoʻomanawanui i nā wela kiʻekiʻe.Hoʻohana ʻia no ka hana ʻana i nā forgings e koi ai i ka ikaika kiʻekiʻe a me nā ʻāpana hoʻopau a me nā ʻāpana ʻoi aku ka nui ma mua o ke kila 4135, e like me nā mīkini nui no ka locomotive traction, booster transmission gears, hope axles, connecting rods a me nā kiʻi puna i hoʻouka nui ʻia.

Hōʻike

| inoa mea kūʻai | AISI ASTM 4130 4135 4140 Alloy Steel Bar | |

| Mea waiwai | ASTM | 4130,4135 4140,4145H |

| DIN | 1.7218 1.7225 1.7220 | |

| GB | 30CrMo 35CrMO 42CrMo | |

| Kūlana | GB/T799, ASTM A29, A108, A321, A575, BS970, DIN1652, JIS G4051 | |

| OD | 6mm a 600mm | |

| Ili | Ua pena ʻeleʻele, ʻaʻahu ʻole, i ʻoni ʻia, i uhi ʻia ma Chrome | |

| Nā kikoʻī | pā pōʻai | 8mm~800mm |

| pā kihi kihi | 3mm * 20mm * 20mm ~ 12mm * 800mm * 800mm | |

| Paʻa huinaha | 4mm * 4mm ~ 100mm * 100mm | |

| pā pālahalaha | 2*10mm~100*500mm | |

| Hexagonal | 4mm~800mm | |

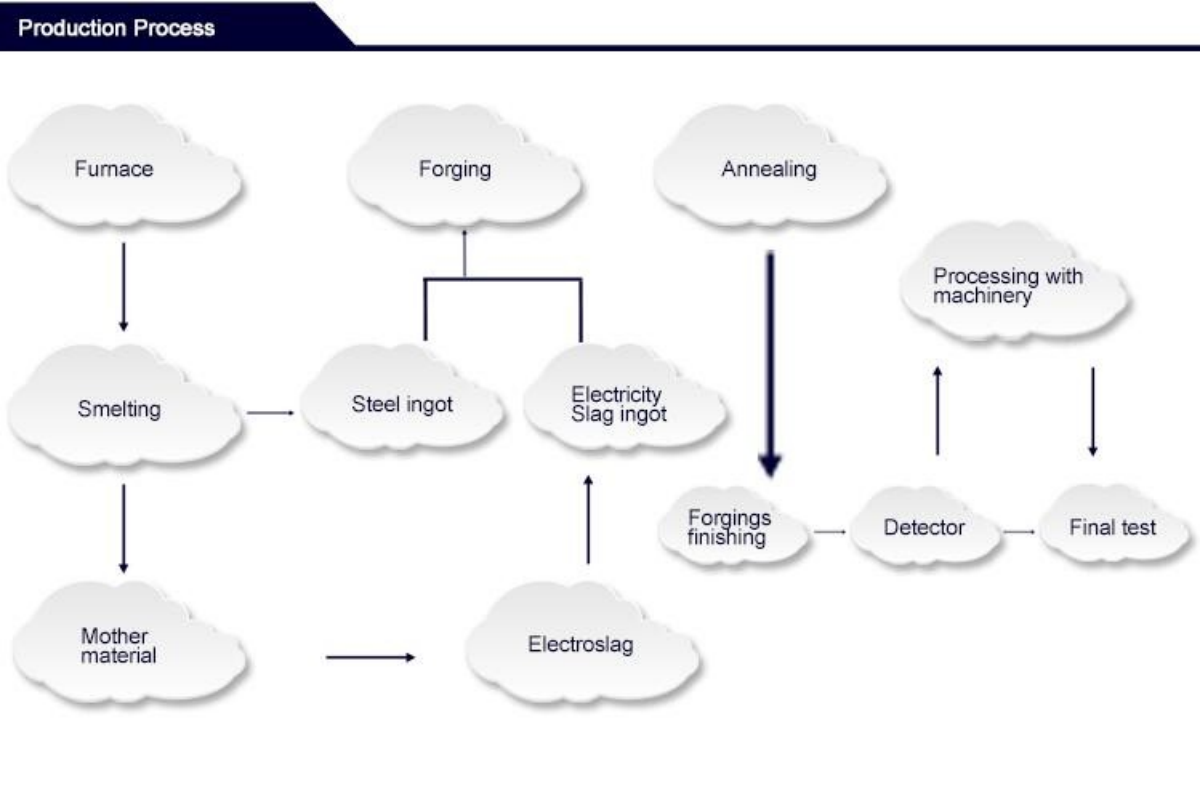

| Kaʻina hana | Hoʻoheheʻe ʻia ka umu uila, hoʻopaʻa ʻia a hoʻopili ʻia, huli ʻia ka pahu pōʻai. | |

| ʻoʻoleʻa: | HBS 217Max (He ʻokoʻa me ka mālama wela) | |

| Hoao UT | SEP 1921/84/2 C/c papa. | |

| Hoʻomanawanui | Dia -0/+ 0~5mm, Mānoanoa -0/+ 0~5mm, Laulā: -0/+ 0~10mm. | |

| Ka lōʻihi | 2m,4m,5.8m,6m,11.8m,12m a i ole e like me ka makemake. | |

| Pūʻolo | Hoʻopili pono kai. | |

| Kūlike like ʻole | |||

| AISI | GB | DIN | JIS |

| 4130 | 30CrMo | 1.7218 | SCM420 |

| 4140 | 42CrMo | 1.7225 (42CrMo4) | SCM440 |

| 4135 | 35Crmo | 1.7220(34CrMo4) | SCM432 |

| 4145H | — | — | — |

Hoʻohui Kimia

| Ka Hui Kemika (%) | |||||||

| Papa | C | Si | Mn | P | S | Cr | Mo |

| 4130 | 0.28-0.33 | 0.15-0.35 | 0.40-0.60 | ≤0.035 | ≤0.040 | 0.80-1.10 | 0.15-0.25 |

| 4140 | 0.38-0.43 | 0.15-0.35 | 0.75-1.0 | ≤0.035 | ≤0.040 | 0.80-1.10 | 0.15-0.25 |

| 4135 | 0.33-0.38 | 0.15-0.35 | 0.75-0.9 | ≤0.035 | ≤0.040 | 0.80-1.10 | 0.15-0.25 |

| 4145 | 0.43-0.48 | 0.15-0.35 | 0.75-1.0 | ≤0.035 | ≤0.040 | 0.80-1.10 | 0.15-0.25 |

Na Waiwai Mechanical

| Nā hiʻohiʻona: |

| 1.Low kila kila i loaʻa ka molybdenum a me ka chromium e like me nā mea hoʻoikaika; |

| 2.Excellent mai ka fusion weldability kuana; |

| 3. Hiki ke hoʻopaʻapaʻa ʻia ka huila e ka mālama wela. |

Hoʻomanawanui

| Kūlana Hoʻouna |

| 1.Hot rolled |

| 2.Annealed |

| 3. Hoʻoponopono ʻia |

| 4. Hoʻopiʻi a hoʻonāukiuki |

Nā kūlana o ka mālama wela

1.Annealing: 880 ℃ Hoʻoluʻu kapuahi

2.Normalization: 880 ~ 870 ℃ Ea hoʻoluʻu

3. Hardening: 820 ~ 870 ℃ ʻO ka wai anuanu

4. Tempering: 550 ~ 650 ℃ Hoʻolili wikiwiki

Hiki ke kiʻi ʻia nā Mechanical Properties e ka mālama wela like ʻole.

Pūʻolo

1.Ma nā pūʻolo, kēlā me kēia pūʻolo kaumaha ma lalo o 3 tons, no ka liʻiliʻi o waho

ke anawaena pa poepoe, kela puolo me 4 - 8 mau kaula kila.

2.20 kapuaʻi pahu i loaʻa ka ana, ka lōʻihi ma lalo o 6000mm

3.40 kapuaʻi pahu i loaʻa ka ana, ka lōʻihi ma lalo o 12000mm

4.By bulk moku, Freight uku haʻahaʻa e ka nui ukana, a nui

ʻAʻole hiki ke hoʻouka ʻia nā nui kaumaha i loko o nā ipu hiki ke hoʻouna ʻia e ka ukana nui

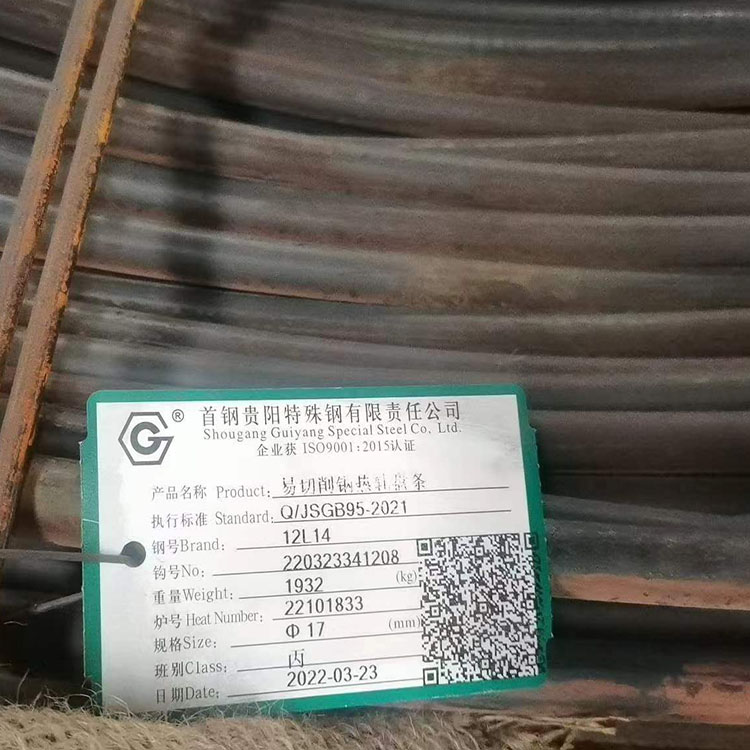

ʻO ka hōʻoia maikaʻi

1.Strict e like me nā koi

2. Laʻana: Loaʻa ka laʻana.

3. Nā ho'āʻo: ho'āʻo paʻakai paʻakai/Tensile ho'āʻo / Eddy manawa / Chemical haku ho'āʻo e like me nā mea kūʻai mai noi

4.Certificate: IATF16949, ISO9001, SGS etc.

5. EN 10204 3.1 Hōʻoia

ʻO SAE4130 ke kila pōʻai he kila kumu kūʻai.ASTMA29/A29M-04 maʻamau.Kaumaha ʻāina kūpono: 30CrMo Kaumaha Kepani kūpono: SCM430 (SCM2) Kaumaha Kelemānia kūpono: 34CrMo4 (1.7220)

4130 structural steel he kiʻekiʻe ka ikaika a me ka paʻakikī, kiʻekiʻe hardenability, a me ke anawaena hardenability koʻikoʻi o 15-70mm i ka aila;He maikaʻi nō hoʻi ka ikaika wela o ke kila, me ka ikaika o ka wela kiʻekiʻe ma lalo o 500 ℃, akā ua emi nui kona ikaika ma 550 ℃;I ka wā o ka mea hoʻoheheʻe i ka palena haʻahaʻa, maikaʻi loa ke kuʻi ʻana, akā inā kokoke ia i ka palena kiʻekiʻe, ʻoi aku ka maikaʻi o ka weldability, a koi ʻia ka preheating ma luna o 175 ℃ ma mua o ka wili;He maikaʻi ka machinability a me ka plasticity maʻalahi i ka wā anuanu deformation;I ka wā o ka hoʻomaʻamaʻa ʻana i ka wela, loaʻa nā ʻano like ʻole o ka huhū ma ka laulā o 300-350 ℃;Aia ka manaʻo e hana i nā kiko keʻokeʻo.

Hoʻohana nui ʻia ʻo SAE4130 i ka ʻoihana mīkini ʻenehana liʻiliʻi e hana i nā ʻāpana kinai a me nā ʻāpana me nā ʻāpana nui e hana ana ma lalo o ke kūlana koʻikoʻi, e like me nā shafts, spindles, a me nā huila hoʻokele haʻahaʻa kiʻekiʻe, bolts, double head bolt, gears, etc;Hoʻohana ʻia i loko o ka ʻoihana kemika e hana i nā ʻāpana welded, nā hale welded i haku ʻia me nā papa a me nā paipu, a me nā conduits kiʻekiʻe me ka mahana ʻaʻole iʻoi aku ma mua o 250 ℃ e hana ana i loko o kahi ʻano me ka nitrogen a me ka hydrogen;I ka ʻoihana hana o nā turbine mahu a me nā paila, hoʻohana ʻia ia e hana i nā mea paʻa no ka hana ma lalo o 450 ℃, nā flanges a me nā uhi flange ma lalo o ke kaomi kiʻekiʻe ma lalo o 500 ℃.