-

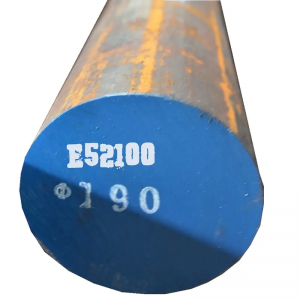

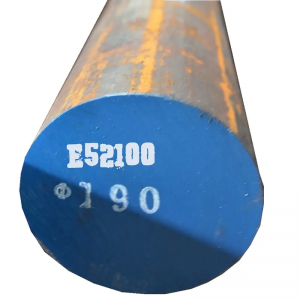

Kaulana Steel GCr15 AISI 52100 100Cr6 a me SUJ2 Bearing Bar Poe

inoa: Kaulana Steel GCr15 AISI 52100 100Cr6 a me SUJ2 Bearing Bar Poe

ʻAno: ʻOli anu / ʻōwili wela / Forging

Papa:1.3505 100Cr6 AISI 52100 Gcr15 SuJ2

Nui:OD10mm-1600mm

Kūlana:Hana maʻamau ;Hanaia ;Ua kinai ;Huhū, Ke kalai ana

Mill Test Certificate: EN10204 3.1

Kaʻina hana: Piʻo/ ʻoki ʻia/Poli ʻia/Paʻa ʻia ʻo Chrome

-

ST52 ST52-3 S355JR S355J0 ʻO ka lāʻau kila paʻa paʻa poʻe

Inoa: ST52 ST52-3 S355JR S355J0 Paʻa lāʻau lāʻau lāʻau a puni

ʻAno: Hoʻowili wela/ Hoʻopaʻa ʻia/ ʻōwili ʻia ke anu

Papa: ST52 ST52-3 S355JR S355J0

Nui:OD 6mm-1200mm

Kūlana:ʻOlokaʻa wela, Annealed/QT/Forged

Mill Test Certificate: EN10204 3.1

Kaʻina hana: Piʻo/ ʻoki ʻia/Poli ʻia/Paʻa ʻia ʻo Chrome

-

S355J2 DIN 1.0577 ST52-3 Wela Hoʻomoe ʻia ʻO ke kila pōʻai pōʻai.

inoa:S355J2 DIN 1.0577 ST52-3 Wela Hoʻomoe ʻia ʻO ke kila pōʻai pōʻai.

ʻAno: Hoʻowili wela/ Forged

Papa: S355J2 DIN 1.0577 ST52-32 (a i ʻole noi mea kūʻai aku)

Nui:OD 6mm-1200mm

Kūlana:ʻOlokaʻa wela, Annealed/QT/Forged

Mill Test Certificate: EN10204 3.1

Kaʻina hana: Piʻo/ ʻoki ʻia/Poli ʻia/Paʻa ʻia ʻo Chrome

-

ʻO ka ʻōleʻa wela S460 Q460C S460M S460ML S460NL S460NH Steel Poʻa

inoa:ʻO ka ʻōleʻa wela S460 Q460C S460M S460ML S460NL S460NH Steel Poʻa

ʻAno: Hoʻowili wela/ Forged

Papa: S460 Q460C S460M S460MLS460NL S460NH

Nui:OD 6mm-1200mm

Kūlana:ʻOlokaʻa wela, Annealed/QT/Forged

Mill Test Certificate: EN10204 3.1

Kaʻina hana: Piʻo/ ʻoki ʻia/Poli ʻia/Paʻa ʻia ʻo Chrome

-

AISI 4130 SCM430 25crmo4 1.7218 Alloy Round Bar Engineering Steel

inoa:AISI 4130 SCM430 25crmo4 1.7218 Alloy Round Bar Engineering Steel

ʻAno: Hoʻowili wela/ Hoʻopaʻa ʻia/ ʻōwili ʻia ke anu

Papa: AISI 4130 SCM430 25crmo4 1.7218

Nui:OD 6mm-1200mm

Kūlana:ʻOlokaʻa wela, Annealed/QT/Forged

Mill Test Certificate: EN10204 3.1

Kaʻina hana: Piʻo/ ʻoki ʻia/Poli ʻia/Paʻa ʻia ʻo Chrome

-

SAE8620H Paʻa Poʻa Poʻo /GB 20CrNiMo Paʻa kila

ʻO SAE8620 ka pahu kila kila he kila kila.ʻO ke kūlana hoʻokō ʻo ASTM A29/A29M-04.Ua like ia me 20CrNiMo ma Kina, he kila hoʻopaʻa paʻa ʻia ʻo Cr-Ni-Mo i hoʻohana nui ʻia no ka carburization a me ka carbon nitrogen co carburization.

-

AISI 4140 SCM440 DIN 42CrMo4 1.7225 Forged Alloy Steel Round Bar

Ua wehewehe ʻia ʻo AISI 4140 ma ke ʻano he kila kila haʻahaʻa nona ka 1% Cr-Mo e like me ka hoʻoikaika ʻana i nā mea hoʻohuihui. ʻilihune i ka weld hiki i nā hiʻohiʻona.AISI 4140 ka mea maʻamau i hoʻolako ʻia i ke kūlana quenched a me ka paʻakikī 28-32HRC.

-

1045 CK45 S45C GCr15 4140 ʻO nā lāʻau paʻa paʻa ʻia Chrome

I loko o nā ʻōhua optical precision, loaʻa mau nā koi no ka paʻakikī o ka ʻili.ʻO ke kumu o ka paʻakikī o waho e hoʻomaikaʻi i ka pale ʻana i ke kapa.No nā mea metala, ʻoi aku ka paʻakikī o ka paʻakikī, ʻoi aku ka paʻa o ka lole.Eia naʻe, ʻoi aku ka paʻakikī o ke kumu, ʻoi aku ka haʻahaʻa o ka paʻakikī, a me ka haʻahaʻa o ka haʻahaʻa haʻahaʻa a me ka pale ʻana i ka hopena.No laila, no nā koi koʻikoʻi koʻikoʻi: ka paʻakikī o waho a me ka paʻakikī o loko.

-

Huli i ka lepo a me ka pahu kila i hooleleia TGP

Loaʻa i kā mākou hui ka mana hana o 20000 tons / makahiki, ʻenehana hana kiʻekiʻe, ʻoi aku ka maikaʻi o ka huahana, a me nā huahana me ke kiʻekiʻe kiʻekiʻe, kiʻekiʻe pololei, a me ka pōʻai kiʻekiʻe.

-

ASTM AISI 1212 1215 1140 1144 ʻOki ʻoki kila kila

ʻO ASTM AISI 1212 1215 1140 1144 ʻO ka ʻoki ʻoki ʻoki manuahi he kila sulfur medium-low carbon free-cutting steel, ʻoi aku ka maikaʻi o ka ʻoki ʻana i hoʻohālikelike ʻia me 10 # 25 # 35 # 45 # kila, ASTM 1212 1215 1140 1144 hiki ke hoʻonui i ke ola mea hana e ʻehā. manawa, hoʻonui i ka huahana ma 30%, a ʻoi aku ka ikaika a me ka paʻakikī.

-

ASTM AISI 12L13 12L14 12L15 ʻOki ʻoki kūʻokoʻa hao hao

ʻO 12L13 12L14 12L15 he ʻoki kila kila.ʻO ke kila ʻoki manuahi ke ʻano o ke kila e maʻalahi ke ʻoki (e like me ka huli ʻana, ka wili, ka huki ʻana, ka hoʻolālā ʻana, ka wili ʻana, a me nā mea ʻē aʻe), ʻike ʻia hoʻi ʻo ia ka mea hana mīkini mea hana maʻalahi, i hoʻopau ʻia e like me ke kila aunoa.He mea maʻalahi ka ʻoki ʻana i ke kila kila, maʻalahi ka ʻoki ʻana i ke kila (huli, wili, kaha kiʻi, hoʻolālā, drilling, etc.) ʻoki ʻana i ke kila, ʻike ʻia hoʻi ʻo ia ka mea hana mīkini mea hana kila, i kapa ʻia ʻo ke kila otometi.Hana ʻia ia e hoʻololi i ka mīkini mīkini a me ka hana laina kahe.

-

Paʻa Paʻa kila no ka mīkini hoʻoheheʻe ʻia

Injection Molding machine tie bar he alakaʻi ia no ka neʻe ʻana o ka platen mold, hana maʻamau ia e nā mea 4140 me ka chromed paʻakikī ma ka ʻili, ʻoiai hiki ke hoʻohana pū me SAE1045 S45C, CK45 40Cr, 38CrMoAla mea.Hiki i ka ʻeleʻele a me ka ikaika ke hāʻawi i ka leo haʻahaʻa a me ka hoʻopili pololei ʻana o ka injection